Inter-array cable layout optimisation

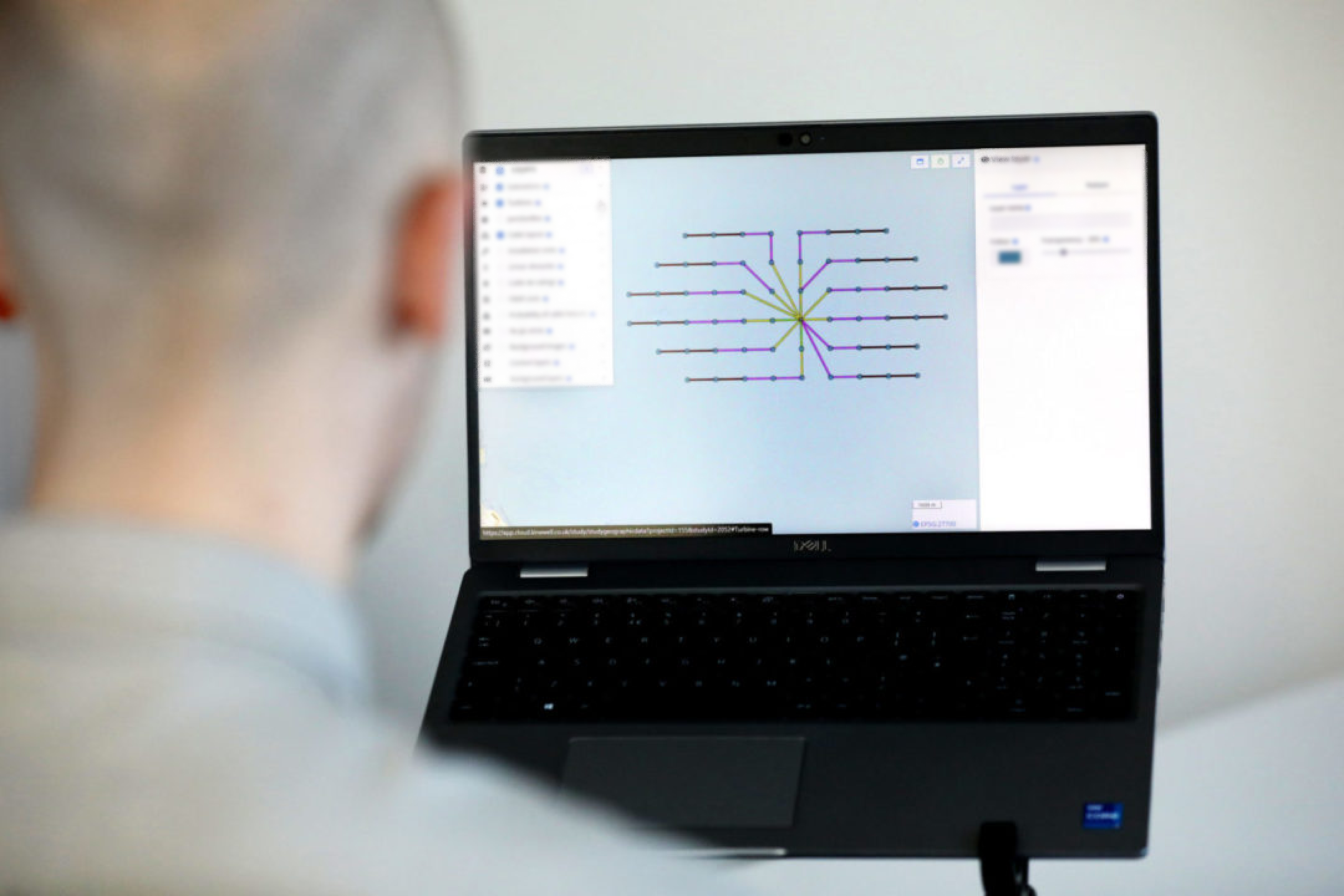

Kinewell Layout Optimisation of Cable (KLOC) rapidly designs optimised inter-array cable layouts for offshore wind farms.

Save 20% of CAPEX over project lifetimes

KLOC reduces total required cable length, lowering CAPEX, while also reducing electrical and unavailability losses to maximise energy sales.

Jumpstart your productivity

Scale up your scenario modelling and de-risk key decisions such as substation location using our rapid optimisation framework and easy-to-use web application.

Automation of the cable layout design allows engineers to focus on areas where they’re needed the most.

Suitable for both floating and fixed wind farms

In addition to static cable layouts, KLOC models dynamic cables and avoids mooring systems in floating wind farms.

Innovative cable systems making use of subsea junction boxes can also be optimised.

Save time and money on seabed surveys

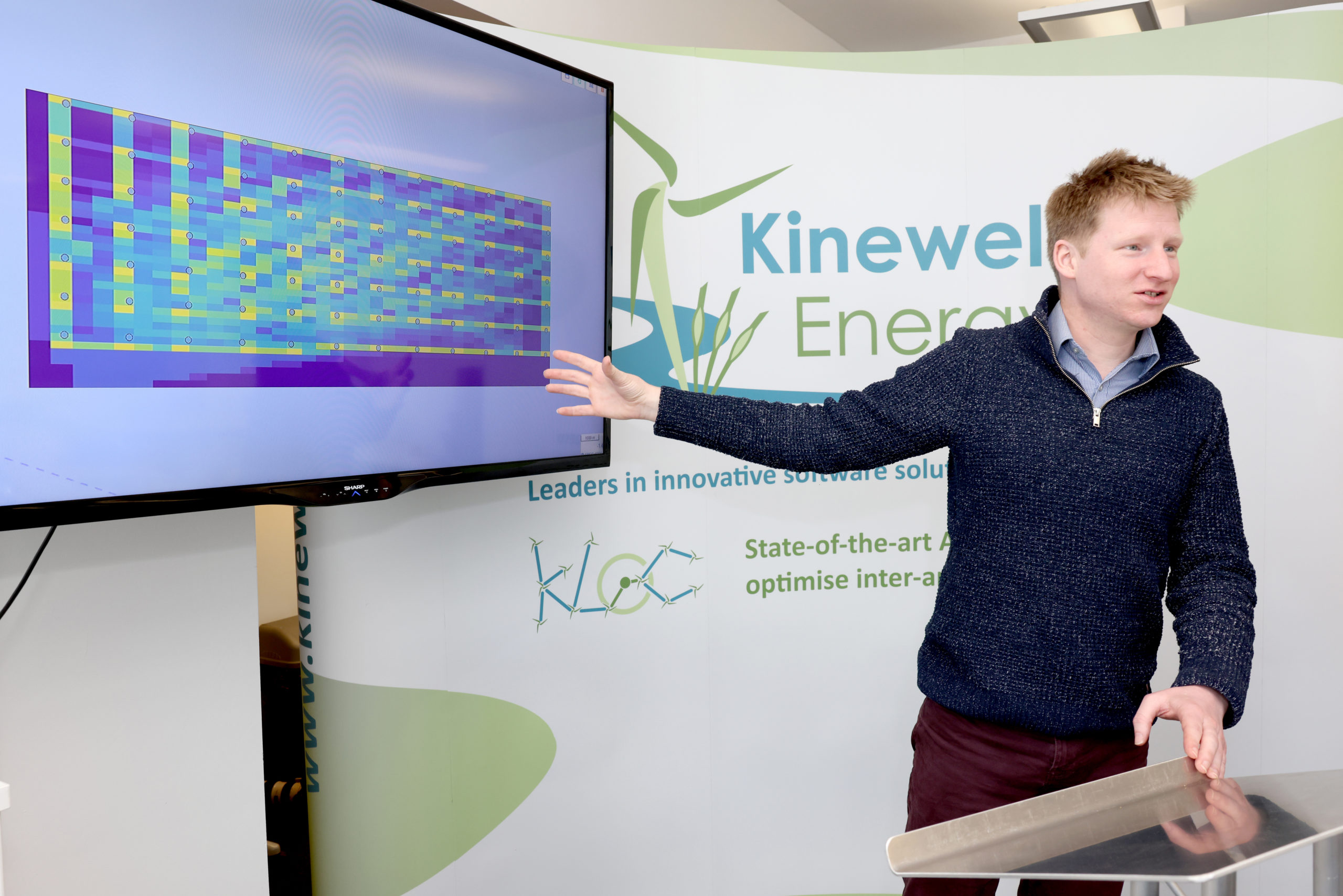

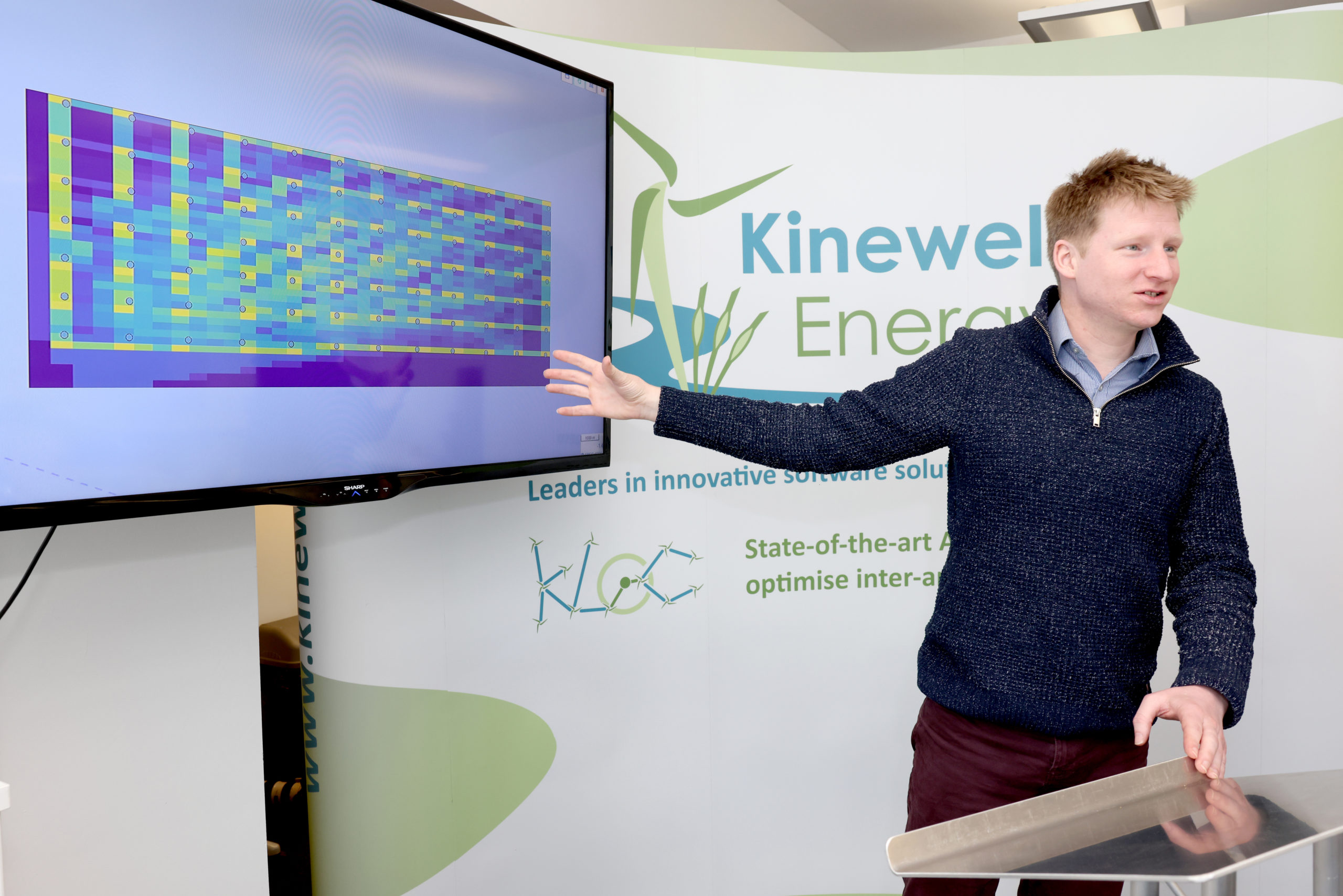

Seabed surveys start around five years before construction and cost £8m for a 1 GW offshore wind farm. KLOC’s probabilistic heatmapping software can reduce your project costs and lead times by eliminating the need to survey undevelopable seabed.

The heatmap forecasts likely cable locations early in a project enabling lower cost seabed surveys as well as supporting critical decisions such as export route planning.

Why use KLOC?

Inter-array cable purchase and installation costs an estimated 360m/GW – typically 11% of total CAPEX.

Using advanced machine learning methods, KLOC produces economically optimised layouts with greater reliability, usually saving 20% of cable system capex, whilst streamlining early stage development.